Introduction of twin-screw extrusion equipment for PLA polylactic acid/starch-based biodegradable materials

Date:2021-06-15

Environmentally friendly packaging, green innovation

Introduction to twin-screw extrusion equipment for PLA polylactic acid/starch-based biodegradable materials

Shantou Dacheng Environmental Protection Precision Machinery Technology Co., Ltd.

Abstract: PLA polylactic acid/starch-based biodegradable material, as an environment-friendly material, has gradually replaced some petroleum-based plastics, and processing equipment plays an important role in broadening the application of the material significance. This article expounds the processing characteristics of biodegradable materials at this stage, and introduces the green performance and technological innovation of the material extraction equipment, and finally makes an outlook on the future development direction of the market.

Key words: PLA polylactic acid; starch-based biodegradation, twin-screw material extraction equipment;

1. Foreword:

PLA polylactic acid/starch-based biodegradable material is a new type of bio-based and fully regenerable biodegradable material, which is made from starch raw materials proposed by renewable plant resources (such as tamarind, etc.). Starch raw materials are saccharified to obtain glucose, and then fermented from glucose and certain strains to produce high-purity lactic acid, and then chemical synthesis methods are used to synthesize polylactic acid with a certain molecular weight. It has good biodegradability, and can be completely degraded by microorganisms in nature under specific conditions after use, eventually generating carbon dioxide and water, causing no pollution to soil and air, and can be Increase soil fertility, return to nature, and do not pollute the environment, which is very beneficial to the protection of the environment and is recognized as an environmentally friendly material.

Polylactic acid is a new type of polyester material, because its properties are similar to existing plastics such as polyethylene, but it can be completely degraded by microorganisms in nature, and has excellent biocompatibility. It is an important alternative material for pollution problems, and has great potential in the fields of medical and health care and home textiles such as fast food boxes, express bags, tableware, shopping bags, moisturizing mulch, insulation boxes, etc.

Product advantages:

1. Starch - natural raw material: natural starch is used as raw material, which can be supplied sustainably, so that natural resources can be reused and circulated endlessly.

2. Degradation - safe biodegradation: the raw materials are natural polymer compounds, which can be degraded in the natural environment.

3. Environmental protection - green environmental protection: After the product is used, it can be quickly degraded by microorganisms in the natural environment and become plant nutrients. It truly comes from nature and returns to nature, effectively solving the problem of white Environmental damage caused by color pollution.

4. Health - non-toxic: the raw materials are natural, the production process is sterile, and the disinfection and inspection are strict. After the product is degraded, it will not cause poisoning to the soil and air, and no harm of secondary pollution.

5. Low carbon - strong substitution: it can replace the plastic products with oil as the raw material and the paper products with the wood as the raw material.

6. International standards: fully comply with the "4R+1D" international environmental protection standards (4R: low consumption, green materials, recyclable, reciprocating production, 1D: degradation).

2. Characteristics of raw material processing:

PLA polylactic acid/starch-based biodegradable materials have good processing properties and are suitable for traditional extrusion, injection molding, blow molding and other processing methods. However, due to the unique molecular structure of PLA, as the temperature increases during processing, the viscosity number will drop rapidly, and at the same time, it will cause problems such as a decrease in melt strength, melt fracture, relaxation, and yield reduction. These problems are particularly prominent in some processing processes that require melt strength, such as sheet extruding, forming, and foaming. Therefore, how to improve the melt strength of polylactic acid and improve its processing performance to expand its application prospects has become a new problem in front of the industry.

In view of the unique molecular structure and processing characteristics of PLA polylactic acid/starch-based biodegradation, many domestic and foreign research institutes, universities, and production enterprises have invested a lot of money to study and master its thermal properties and crystallization properties. and melt rheological properties are the key to optimizing its molding process and the quality of finished products. Therefore, a series of effective solutions are introduced through raw material addition and auxiliaries, process temperature adjustment and optimization, and precision equipment design and manufacturing collaboration.

Three, product processing technology: < /strong>

< /strong>

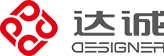

The processing technology of PLA polylactic acid/starch-based products is shown in the figure above, and the process is as follows: the raw materials are co-mixed and then discharged through the twin-screw screw, the die is discharged, the three-roller is cooled, the shape is drawn, the finished product is rolled into a sheet, and then After forming and packaging by air pressure thermoforming equipment or fully automatic blister equipment.

Due to the high water content of ordinary PLA raw materials in the air, it will cause hydrolysis when it is melted and discharged, which will significantly reduce the melt viscosity and molecular weight, resulting in foaming and brittleness of the formed sheet. , hair and other abnormal phenomena. The improvement method usually starts from the following three aspects:

1) By adding processing aids, it can effectively interact with polylactic acid molecules during processing to form a uniform physical network structure (to avoid gel formation) to improve melt strength. Once the melt strength is improved, it can effectively prevent melt fracture during processing, making the processing process more stable, thereby increasing the output. At the same time, it can also improve the quality of products to a certain extent.

2) In the selection of equipment and technology, the equipment usually used is mainly single-screw extruder. Its processing route of "drying and melting and extruding" generally needs to be equipped with a drying system. Two types are directly extruded and molded using a vacuum exhaust twin-screw extruder. Due to the inherent characteristics of a single screw, it is suitable for the requirements of professionals with few production varieties. The production conditions of different raw materials need to be matched with a special screw structure to achieve better efficiency. The twin-screw exhaust gas extraction process has several significant advantages, including obvious energy-saving effect, simple process technology, online compounding, etc. Through the special transformation of twin-screw, the ideal exhaust effect and effective Controlling PLA melt viscosity control can better meet the current market demand for flexible manufacturing.

3) The adjustment process requirements of precision manufacturing equipment for temperature field, due to the unique molecular structure of PLA polylactic acid/starch base, it requires high temperature field during processing, so equipment should be Multi-point temperature heating and cooling to achieve rapid adjustment and precise control.

Dacheng Company is an advanced plastic processing equipment supplier in China. At the same time, it is also a company with a strong sense of social responsibility. It has always been committed to the application and promotion of degradable material processing equipment. As early as 1999 In July 2005, the first-generation degradable sheet machine was developed and produced. In January 2001, the improved second-generation PLA polylactic acid environmentally friendly degradable sheet was launched. In April 2005, the single-screw PLA polylactic acid was environmentally friendly and degradable. The material was successfully developed. In January 2007, the twin-screw PLA polylactic acid environmentally friendly degradable material was successfully developed and launched into the market, and won a number of national, provincial and municipal science and technology awards, and was well received by the industry. The products have been sold to more than 50 foreign cities and more than 30 domestic provinces and cities, etc., and the equipment operates well. Learning the design concepts from abroad, especially in Europe, integrating the latest achievements of scientific research institutes such as universities, and combining Dacheng's own positioning and characteristics, it has cooperated with domestic and foreign universities, research institutes, and biodegradable materials for many times. Business broad and close ties, joint research. Relying on the solid technical foundation and rich experience in the field of plastic processing equipment, the company makes full use of the company's existing imported high-precision equipment to improve the processing accuracy of parts, design and optimize the structure and processing technology of various parts, and improve the overall device performance. At the same time, we will continue to strengthen the work of production, education and research, and strive to develop products with more complete functions to meet broader requirements and make greater contributions to the promotion and application of degradable raw materials.

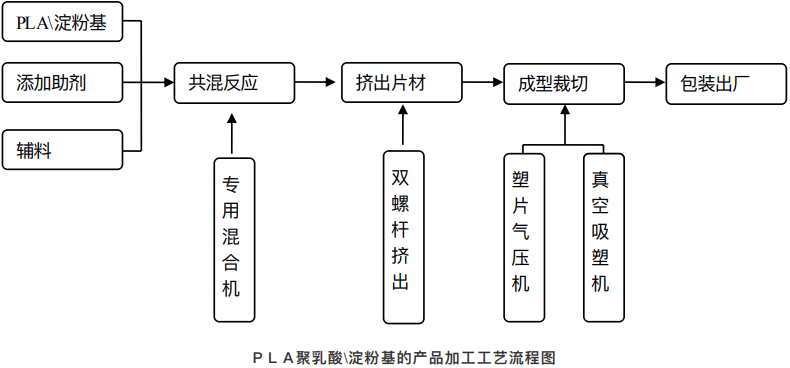

The PLA polylactic acid sheet output equipment designed and manufactured by Guangdong Dacheng Technology Co., Ltd. has the following characteristics:

! It is suitable for the production of PLA polylactic acid/starch-based fully biodegradable sheets, with high output, Low energy consumption and simple operation;

! Compared with domestic similar equipment, the comprehensive energy saving is increased by more than 30-40%.

! Adopt three-stage vacuum evacuation technology and oil-air separation technology:

! Adopt twin-screw optimized combination technology to ensure product quality and stability;

! The power closed-loop feedback control technology and the temperature field of heating and cooling adopt dual PID control technology;

! The whole machine adopts PLC control to realize parameter setting, data operation and feedback, and provide improvement measures in real time.

Fourth, the equipment green innovation point of processing equipment

How to develop PLA polylactic acid/starch-based high-efficiency and high-efficiency material production equipment, through various demonstrations, it is believed that technological innovation, structural optimization, and precision manufacturing are carried out from five links, so as to achieve high output and low energy consumption of equipment, and create domestic high-efficiency PLA. High-end equipment for the production of polylactic acid/starch-based twin-screw materials. 1) Twin-screw combination technology

The twin-screw configuration R&D and design experience accumulated over the years is optimized and combined with advanced software technology. The special double-start screw element and the unique screw combination can realize conveying, plasticizing, mixing and kneading, It has various functions such as shear dispersion, homogenization and homogenization, exhaust and degassing, and pressure build-up and output. Especially in the removal of crystalline water inside the PLA material, it has extremely high efficiency. The specially designed exhaust port is free and unobstructed, so as to achieve low temperature discharge and avoid thermal degradation of PLA;

) Vacuum exhaust technology

Multi-stage forced exhaust is efficient and safe to ensure that the PLA material does not dissolve in the process of melting and plasticization, and no crystal points are generated. Special three-stage vacuum evacuation technology and oil-air separation technology, ultra-large suction volume and ultra-high vacuum degree, greatly reduce the viscosity reduction of PLA.

3) High-strength roller internal spiral flow channel technology

The internal spiral flow channel structure design of the high-strength roller is equipped with a water temperature control system, so that the roller has precise temperature control and efficient heat transfer effect;

4) Intelligent remote control technology

Through the company's server IDC center industrial data center and industrial data acquisition and analysis software, remote monitoring network equipment, standard motor health detection and analysis system, equipment Energy management optimization system, etc., realize remote monitoring of Dacheng equipment in the customer's factory, collect and store various process data, and analyze process data to optimize production process formula.

5) Equipment manufacturing process craftsmanship

Parts material selection, manufacturing process, processing accuracy, heat treatment and surface treatment, appearance design and other industrial designs are comprehensively studied to ensure equipment stability Reliability, upgrade gear.

V. The green performance of the device is as follows:

1) Multi-component feeding device technology, suitable for controlling the proportion of new material, returning material, color, etc.;

2) Raw material drying technology, low overall energy consumption of the unit and cost saving; 3) The high-torque output unit is equipped with a torque protector;

4) It is equipped with a melt filter with a large filter area, which saves a lot of time and labor consumption for network changing operations;

3) Three Roller calendering roller pressing adopts hydraulic device, with compact structure, convenient layout of auxiliary facilities and simple operation; water temperature system adopts temperature double PID control technology of heating and cooling, etc.;

6) Online trimming and crushing , Conveying and recycling system, special winding structure design, realize online non-stop coil change, unloading device, save a lot of operation time and labor consumption;

7) Online silicon coating system, improve the adaptability of the material improve competitiveness;

8) The high-precision twin-screw output system adopts pressure closed-loop feedback control technology, heating and cooling temperature double PID control technology, etc.;

9) Integrating The machine adopts PLC control to realize the automatic control of parameter setting, data calculation and feedback, alarm and other functions;

10) Advanced dual PID control algorithm technology, real-time statistical analysis of technical data, real-time provision of improvement measures, Ensure that the production process is always under statistical control to improve product quality, accuracy, energy consumption and other performance indicators.

Six. Market application prospects and future prospects:

At present, due to people's lack of understanding of this emerging material, the market has not been fully developed, and the demand is low. Most companies wait and see. The company is small in scale, low in production capacity, and high in production cost. In the market competition, the sustainable ability is weak. On the other hand, due to the lack of large-scale production capacity, the penetration rate of use and the stability of products cannot meet the needs of the market, which affects the development of the industry. However, with the increasing shortage of international crude oil resources, the increase in the pressure of oil supply, and the increase in the pressure of urban waste treatment and white pollution, the economic and environmental significance of the PLA polylactic acid/starch-based biological material industry has gradually become more and more important. Prominent, the internal driving force of industrial development continues to increase. Secondly, the implementation of environmental protection requirements from the "plastic restriction order" to the "plastic ban order" at home and abroad, supported by relevant national policies or laws, accelerates market cultivation.90% of the disposable plastic beverage bottles were recycled before 2010, and PLA polylactic acid/starch-based materials are green, environmentally friendly, resource-saving, etc., and are gradually becoming a new leader leading the contemporary world's technological innovation and economic development industry. Therefore, the PLA polylactic acid/starch-based biomaterial industry has broad market prospects.

In the market environment where Industry 4.0 and the Made in China 2025 wave continue to surge, industrial changes characterized by the integration and development of a new generation of information and communication technology and manufacturing are emerging on a global scale, and intelligent manufacturing has become the development of manufacturing industry. the main direction. The promotion and application of Internet + industrialization promotes the upgrading of products. Product production includes intelligent applications such as raw material modification, process optimization, equipment precision manufacturing, and operation mode, breaking through the original mode and adding intelligent Units (including mechanical, sensing, electrical and intelligent software, with memory, perception, calculation and decision-making functions) make equipment operation more convenient and improve product quality and added value. It can realize automatic detection of equipment health status; can automatically manage various process parameters according to product and raw material requirements, realize dynamic setting and storage; can monitor production operation status and automatically adjust; can intelligently optimize various operations parameter. The intelligent unit has built-in artificial intelligence algorithms, and has the ability to learn process parameters. It can find the optimal process parameters of equipment suitable for specific products through limited test sample training, and cooperate with various functional devices to ensure product quality and reduce energy. energy consumption, highlighting the characteristics of greening and intelligence.

Moving towards digitization, automation and intelligence, we strive to create high-efficiency, energy-saving, intelligent and high-quality material and material output equipment, and at the same time meet the green packaging of products, technological innovation, and sustainable development, and constantly expand equipment applications. market, increase the added value of products, and compete with foreign companies with comprehensive cost-effective advantages and excellent quality assurance.